MUSICODE's M42 meeting was live on June

2 yrs ago

Summary and conclusions from the M18 Review Meeting

MUSICODE’s M18 review meeting took place at Porto Palace Hotel located at Thessaloniki, Greece on July 2nd, 2022. Those who did not attend the meeting physically, could participate through the MS Teams virtual platform.

Summary of the context and overall objectives of the project

Organic and Large Area Electronics (OLAE) is a rapidly emerging sector bringing disruptive technological revolutions for industrial applications in Energy, Electronics, Transport, Photonics, Buildings, Lighting & Displays, Health, Wearables, IoT, Agriculture, etc. OLAE are thin (< 1 μm) complex multilayer architectures consisting of stacks of sensitive organic and inorganic nanolayers on long (>100 m) flexible polymer rolls. Their market is estimated to rapidly grow worldwide up to 77.3 B$ in 2029 driven by Organic Photovoltaics (OPVs), Organic Light Emitting Diodes (OLEDs), biosensors, and flexible batteries, amongst others. OLAE are produced by environmentally friendly methods, such as ambient, room temperature, roll-to-roll (R2R) printing processes and are widely expected to contribute to a greener and more sustainable future. However, to unleash the full potential and advantages of OLAE devices, the EU Industry needs novel modelling and design tools to efficiently address screening and uptake of new materials, smart adaptation of processing conditions, and exploration/optimization of new device concepts and architectures. Such tools will enable expeditious and accurate business decisions targeting high efficiency, performance, and manufacturability, while reducing errors, defects, resource waste, and performance variability. MUSICODE is an ambitious project addressing the H2020 Call DT-NMBP-11-2020 “Open Innovation Platform for Materials Modelling” that will develop a novel Open Innovation Materials Modelling Platform which will enable the Organic and Large Area Electronics (OLAE) Industry to expediate accurate and knowledgeable business decisions on materials design and processing for optimization of the efficiency and quality of OLAE device manufacturing. The first three objectives are for this platform to integrate: (a) Material, process, and device modelling with workflows spanning the micro, meso- and macro- scales, validated by expert academic and industry partners. (b) Integrated data management and modelling framework with ontology-based semantic interoperability between scales, solvers, data, and workflows, with industry-accepted material and process modelling parameters and protocols, employing graphical user interface tools for workflow design, analysis, optimization, and decision making. (c) Plug-ins to Materials Modelling Marketplaces, Open Translation Environment, Business Decision Support Systems, etc. and to High Performance Computing infrastructures for workflow execution. The final objective (d) is this platform to demonstrate industrial use-case workflows to optimize OLAE materials selection & design as well as printing and gas-phase manufacturing. The ambition for the MUSICODE platform is to become a central EU repository for workflows, data, metadata, and citable protocols regarding OLAE modelling (materials, materials processing, and device performance) and experimental information about characterization, validation, and processing by wet, printing and gas transport technologies. The MUSICODE Business Plan will ensure the platform sustainability, exploitation, and industrial adoption beyond the project, and setup the preliminary roadmap towards its evolution into a cross-domain modelling platform.

Work performed from the beginning of the project to the end of the period covered by the report and main results achieved so far

The work in MUSICODE is organized in eight interconnected work packages:

In WP1 (Specifications & ontology), a full set of specifications was compiled for: (a) OPV and OLED materials, processes, and devices, (b) modelling tools spanning all length scales, (c) platform architectural diagram, access rules, BPMN models, MuPIF workflows, HPC utilization, (d) data architecture, format and services, (e) ontologies for data, workflows, characterization, etc.

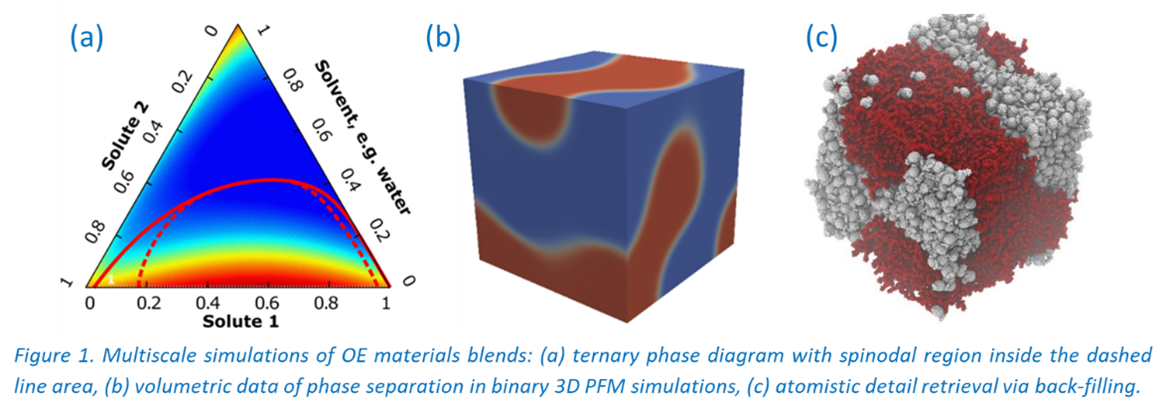

In WP2 (Development of multiscale modelling tools), the modeling methods for the individual scales were developed and MUSICODE-related test cases were established. All physical scales are relevant in the MUSICODE project, starting from the lowest (more-detailed) to the highest (less-detailed) scales: electronic for charge interactions and transport, atomistic for molecular structure, mesoscale for microstructure evolution, and continuum for material processing and device functionality. The different models involve (a) models operating on a specific scale, (b) models used to extract info from a lower scale and use it as input for the next scale (forward mapping), and models that can take a physical domain or system developed in a higher scale and fill it up with details corresponding to a lower state (backward mapping). All together the MUSICODE partners have identified and developed 21 such models. Using these tools, preliminary multiscale simulations were performed on materials electronic properties, on microstructure evolution (Fig. 1),  on slot-die printing and gas phase deposition of materials, and on OPV and OLED device and panel operation.

on slot-die printing and gas phase deposition of materials, and on OPV and OLED device and panel operation.

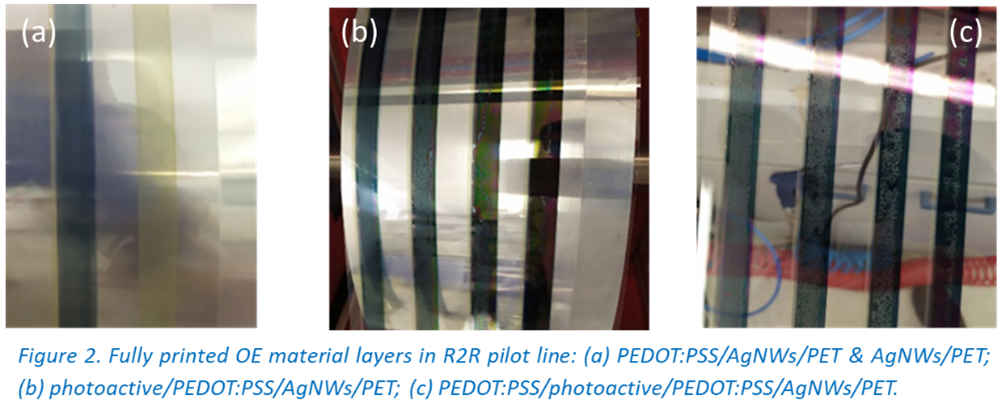

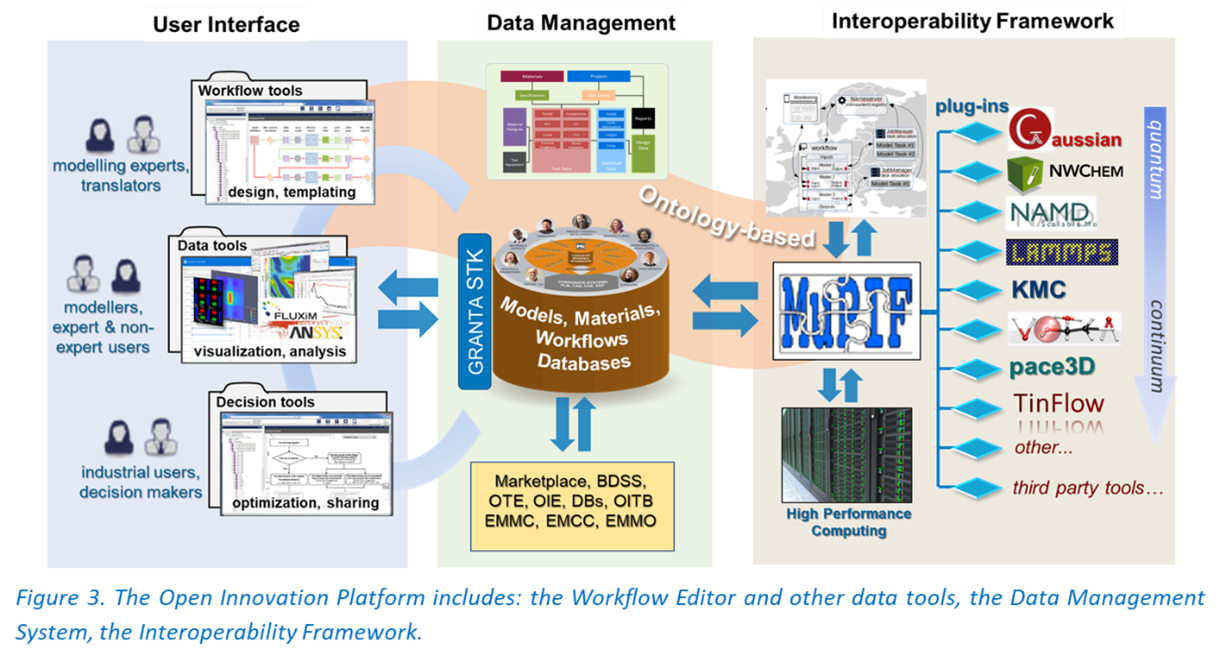

In WP3 (Model validation by analytical characterization), many different functional layers and devices involving different materials and materials combinations were fabricated (Fig. 2). The device types include full functional devices, electron- and hole-only devices, direct and inverted architectures. Methods include spin-coating, slot-die printing, and vapor phase deposition. Detailed measurements of layer thickness vs process conditions, structural, optical and electrical characterization. Emphasis was given in the reproducibility of the fabricated devices, in increasing the confidence level of the extracted physical quantities and in establishing a good correlation between characterization results and device functionality. First steps towards comparing with modelling results on charge carrier mobility have been taken.  In WP4 (Development of Open Innovation Modelling Platform), the Open Innovation Platform started being developed, namely the Interoperability framework, the Data Management System, and the Workflow Editor (Fig. 3). Significant progress in line and beyond what envisioned has been achieved. The first version of the interoperability framework has been released, including plugins to codes, name server, scheduler, and Web based monitoring service. The first version of the Data Management System has been released and direct use of the system also started. The workflow editor has been prepared for integration in the platform with supporting needed BPMN elements and conversion to MuPIF JSON/Python. A generic interface between the individual components has been defined based on standardized http protocol, enabling information sharing and data exchange. First APIs of individual models have been developed with two prototypic simulation workflows demonstrated with test data exchange and steering for specific tasks.

In WP4 (Development of Open Innovation Modelling Platform), the Open Innovation Platform started being developed, namely the Interoperability framework, the Data Management System, and the Workflow Editor (Fig. 3). Significant progress in line and beyond what envisioned has been achieved. The first version of the interoperability framework has been released, including plugins to codes, name server, scheduler, and Web based monitoring service. The first version of the Data Management System has been released and direct use of the system also started. The workflow editor has been prepared for integration in the platform with supporting needed BPMN elements and conversion to MuPIF JSON/Python. A generic interface between the individual components has been defined based on standardized http protocol, enabling information sharing and data exchange. First APIs of individual models have been developed with two prototypic simulation workflows demonstrated with test data exchange and steering for specific tasks.  In WP5 (Cooperation with EU stakeholders for population of the workflows), cooperation with EU stakeholders (EMMC, EMMO, OntoCommons) was commenced to discuss and align OLAE ontology domain. OLAE Simulation Requirement Ontology complete. Simulation platform was interfaced with different HPC resources with support for PBS scheduling and demonstration on UoI-Vikos HPC cluster. Initialized discussions with third-party HPCs. Discussions and preliminary demonstration of integration in MarketPlace. Cooperation with other OIP projects (VICOAT and OpenModel) has been established with several calls, OIP Workshops (3), and a common white paper. MUSICODE activities have been communicated on different events (Greek National Press Conference, NANOTEXNOLOGY 2021, Workshop of NanoME-Commons).

In WP5 (Cooperation with EU stakeholders for population of the workflows), cooperation with EU stakeholders (EMMC, EMMO, OntoCommons) was commenced to discuss and align OLAE ontology domain. OLAE Simulation Requirement Ontology complete. Simulation platform was interfaced with different HPC resources with support for PBS scheduling and demonstration on UoI-Vikos HPC cluster. Initialized discussions with third-party HPCs. Discussions and preliminary demonstration of integration in MarketPlace. Cooperation with other OIP projects (VICOAT and OpenModel) has been established with several calls, OIP Workshops (3), and a common white paper. MUSICODE activities have been communicated on different events (Greek National Press Conference, NANOTEXNOLOGY 2021, Workshop of NanoME-Commons).

In WP6 (User Cases, started on M13), the partners worked on the initial design of all the user cases. These include:

In WP7 (Dissemination, Communication and Exploitation activities), all partners were active for the dissemination and communication of the project and its results to the academic, research, and industrial communities. The exploitable innovations and the ways for their effective exploitation were defined. The General principles of knowledge management and Intellectual Property Rights (IPR) in the context of IPR management were discussed and accepted. The project website, the OwnCloud secure server, social media, and various project dissemination platforms and material were created. Partners made 46 scientific conference presentations and 5 journal publications, organized several training seminars and organized a Summer School on “Multiscale Modelling and Open Innovation Platforms”. Initial discussions on a Business Plan for Market Implementation and future commercialization of the project results, established a key exploitable result (KERs) and made 2 initial market assessments (Molecular Modelling, Display Applications).

In WP8 (Project Management & Administration), the set of rules for ensuring the smooth progress of the project towards its objectives were created. Setup of regular meeting for monitoring and assessing progress. Setup of mailing lists, communication platforms, secure common file storage, communication templates, risk management plan. Setup of the initial data management plan with input from all partners.

Progress beyond the state of the art, expected results until the end of the project and potential impacts

Even though the project has just passed its first 18 months, several achievements in different areas are pushing the technological envelops beyond the state of the art. These are: • The new domain ontology “OLAE Simulation Requirements” (application level), developed in both UML and OWL, a subset and first step towards the more general “Workflow Ontologies”, for the development of which EMMO has established a new task force • The development and release of the multipurpose versatile open-source software “MEL” for mapping electronic (DFT) data to atomistic partial charges and atomic polarizabilities • Multiscale mobility simulations in crystalline and amorphous IDIC. • Successful band gap benchmarking of 1297 3D Perovskite structures • Development of several novel multiscale modelling forward and backward mapping techniques • Phase diagram and PFM simulations of ternary systems • Extension of CFD solver to properly treat low-pressure gas flow line conditions • Implementation of a new approach for self-absorption and photon recycling in OPVs and OLEDs • Successful fabrication of efficient binary and ternary OPV devices • Printed single-carrier electron-only devices with inverted structure • Fully printed single-carrier hole-only devices on flexible substrates (PET) • Estimation of charge carrier mobility in EOD and HOD by SCLC measurements • OVPD deposition of Hydroxyquinolinolato-lithium (LiQ) • Semantic integration and parallel execution in HPCs enabled in MuPIF • Large data structures and storage containers created based on semantics • Definition and release of the alpha version of the DB schema • BPMN editor extended to support new Custom Service Tasks towards an OLAE Workflow Editor, exporting MuPIF JSON/Python and interfacing with the Data Management System • First ever end-to-end workflow (EditorDMSMuPIFHPCMuPIFDMS) demonstrated

Until the end of the project (M48), all the above are expected to further mature towards a fully functional Open Innovation Modelling Platform. Specifically, by M48 MUSICODE is on route to have: • Established semantics and ontologies for the OLAE domain • Interconnected models spanning from the electronic to the device scales • Validated modelling protocols based on the targeted use cases: (a) OLAE materials design, (b) OVPD processes, (c) r2r printing processes • Established end-to-end modelling capabilities between Workflow Editor, DMS and MuPIF, with access to data and metadata to all materials, workflows for all processes, APIs for all models, and integration to several HPC centers. • Links to Marketplaces and a robust business plan

These developments have significant socio-economic impacts and wider societal implications: • Streamlined modelling into one seamless modelling workflow, significantly empowering both expert and non-expert (industry) modellers/users. This will have a strong impact to the strengthening of the efficiency, innovation, and competitiveness of industrial manufacturing processes for OLAE and other high-tech products, benefiting EU’s SME and industrial stakeholders to gain a leading position in the global markets. It will enable industrial stakeholders to design, test and validate traceable and custom simulation workflows in OLAE industrial manufacturing involving printing & vacuum processes. • Rapid deployment of modelling solutions is extremely important for industries when large number of new candidate materials appear every year and a multitude of process variations are available. Workflow design flexibility and rapid feedback from modelling also enables new developments and applications in sensing, wearables, communications, IoT, etc. This will decrease the time and the iterations needed for selecting new materials and material combinations and enable more efficient and targeted experimentation with specific materials and processing routes. • Reuse of material modelling knowledge and expertise in different industrial sectors enabling cross-industry fertilization. The impact of facilitating cross-domain continuity will be achieved through immediate integration of the platform models to other types of materials, devices, and products, and work towards eliminating the gaps in translation. • Finally, in terms of societal implications, it will increase the employment opportunities in EU Industries by boosting their competences in making fast decisions on the design of materials and devices, it will increase of digital skills of experts and workers in industry and contribute to the employment of many scientists and technicians.